FIRST OF ALL

Hi all,

I feel its about time I gave everyone who reads this blog a bit of an update on what is happening with board a week.

I think the first thing i have to really say is that I am still designing boards on a semi regular basis I still have much to learn and want to continue making boards.

I think one thing I i have had to except is that currently I am not able to design a board a week, and I is not due to drive to do it. I have other responsibilities that need to be met first whether that is to my family, my work or just to have a little time for myself. The hard thing is to admit is I can't do it all even though I try.

I think the other think I have to keep in mind is not to be too hard on myself about all of this, I think just making little strides towards getting something completed is as good as going heavily from start to finish and being frustrated when I can't achieve this goal. I think I discovered that in week 4 trying to complete the bubble watch in one straight run proved not to work. that one i will come back to soon. I the meantime i have learnt far more about the STM32 platform which will allow me to go back and complete it.

WHERE I AM NOW

As BAW is at the moment I'm putting the finishing touches to Week 9 M0GO a USB Device Dev Board. I think after that it will be a revisit to Bubble Watch.

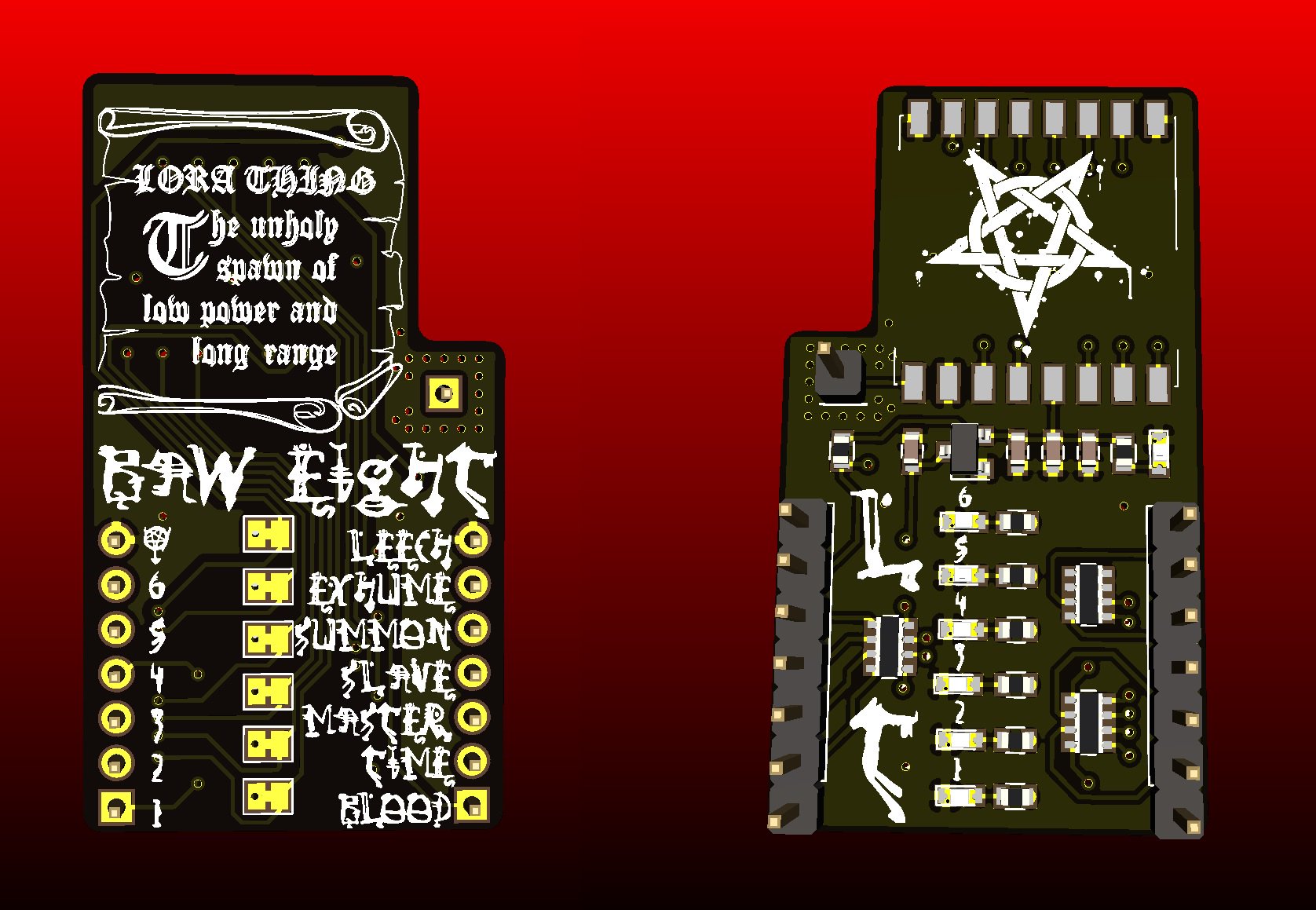

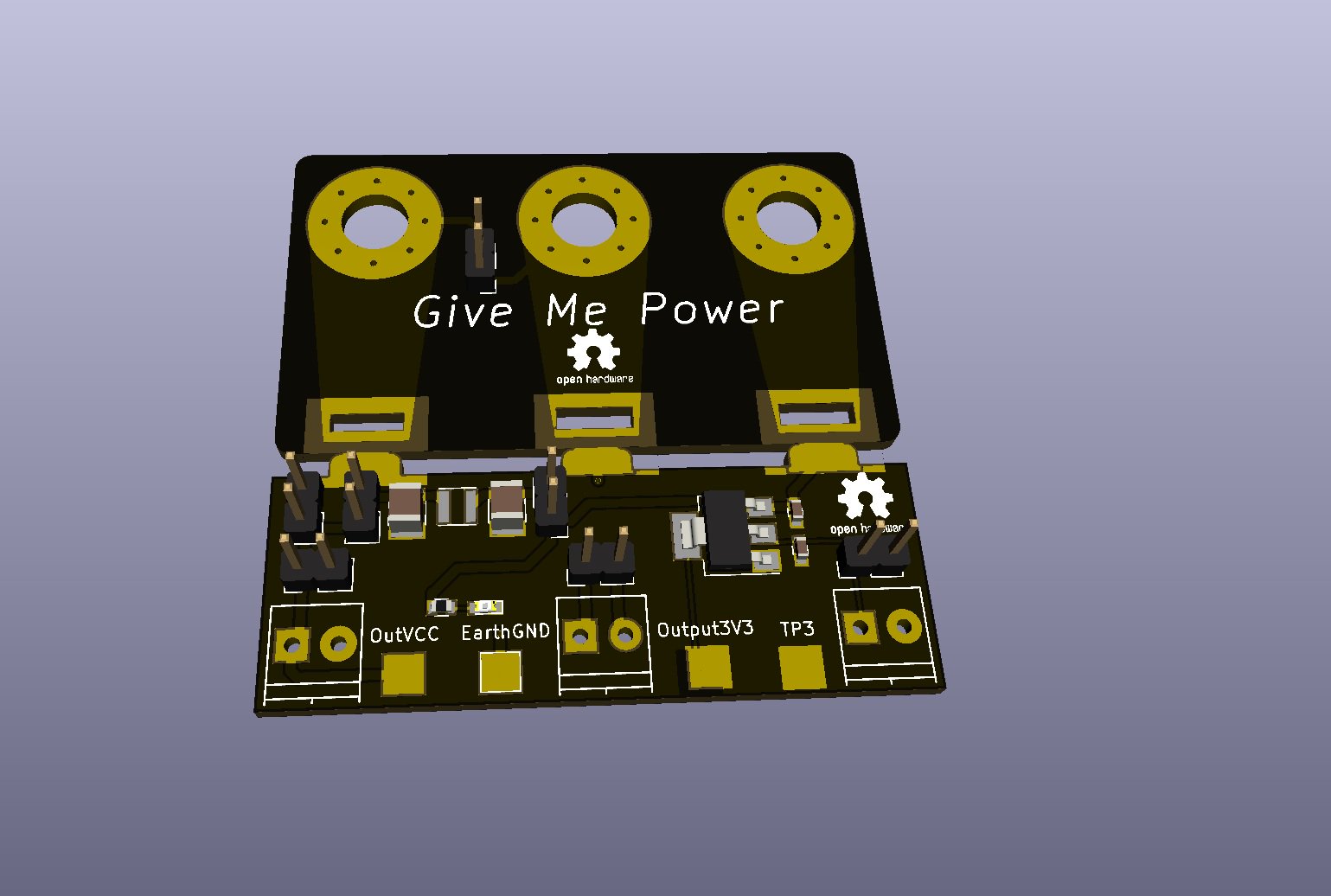

On the subject of having these boards made, I have just send of the Geber files for both Week 8 LoRA Thing and Week 7 GiveMePower hopefully will have those before Christmas. I think I have missed the boat for doing a board for Christmas but defiantly have something in mind for valentines.

AND FINALLY

I would like to take this moment to say a big thank you to everybody that has encouraged me to do this either with friendly words or likes and retweets. I have I continue to be of some interest and hope that others can learn from my mistakes.Please continue you support and all updates are on my Git Repo https://github.com/rabid-inventor/board-a-week